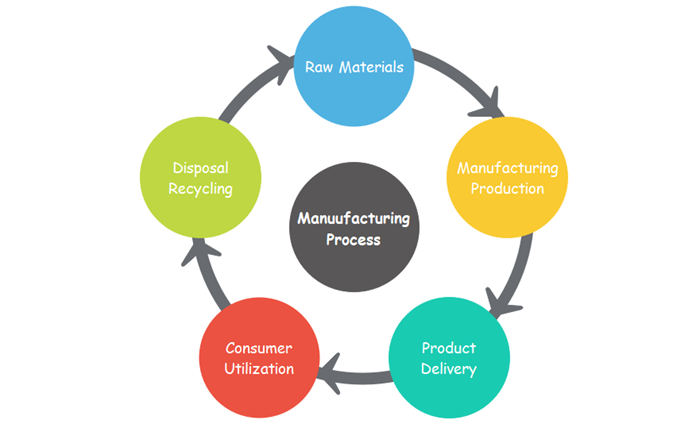

This is done by adding value through the means of changing the shape, physical appearance, or chemical composition, bringing the work material closer to the desired finished component or product. This classification of manufacturing processes pertains to the transformation of completed work materials to an advanced form or state. Read on to learn more about each classification. This way, organizations can further identify the type of process that best fits their production needs, customer demands, and sales forecasts. Prior to knowing the various types of manufacturing processes, it’s important to understand the 2 major classifications they may fall under. In the bigger picture, Good Manufacturing Practices (GMP) cover every aspect of common manufacturing processes to combat risks and promote quality and workplace safety. Moreover, computers, robots, and cloud-based technology are responsible for the automation of the stages involved in the overall manufacturing system, helping make it streamlined and efficient in the long run. The needed resources and manpower can also differ to meet the unique needs of traditional manufacturing processes or even advanced manufacturing processes.

Getting started with Safet圜ulture Platformĭepending on the type of products being manufactured, the methods involved in the entire manufacturing process may be considered simple or complex and require varying levels of supervision, automation, and control.

MANUFACTURING PROCESSES ISO

ISO 45001:2018 Occupational Health & Safety Management.ISO 14001:2015 Environmental Management.

0 kommentar(er)

0 kommentar(er)